- Home

- Company

- Corporate Information

- Production Locations

OUR PRODUCTION LOCATIONS

Where we make Hilti tools, consumables and technologies

Schaan, Liechtenstein

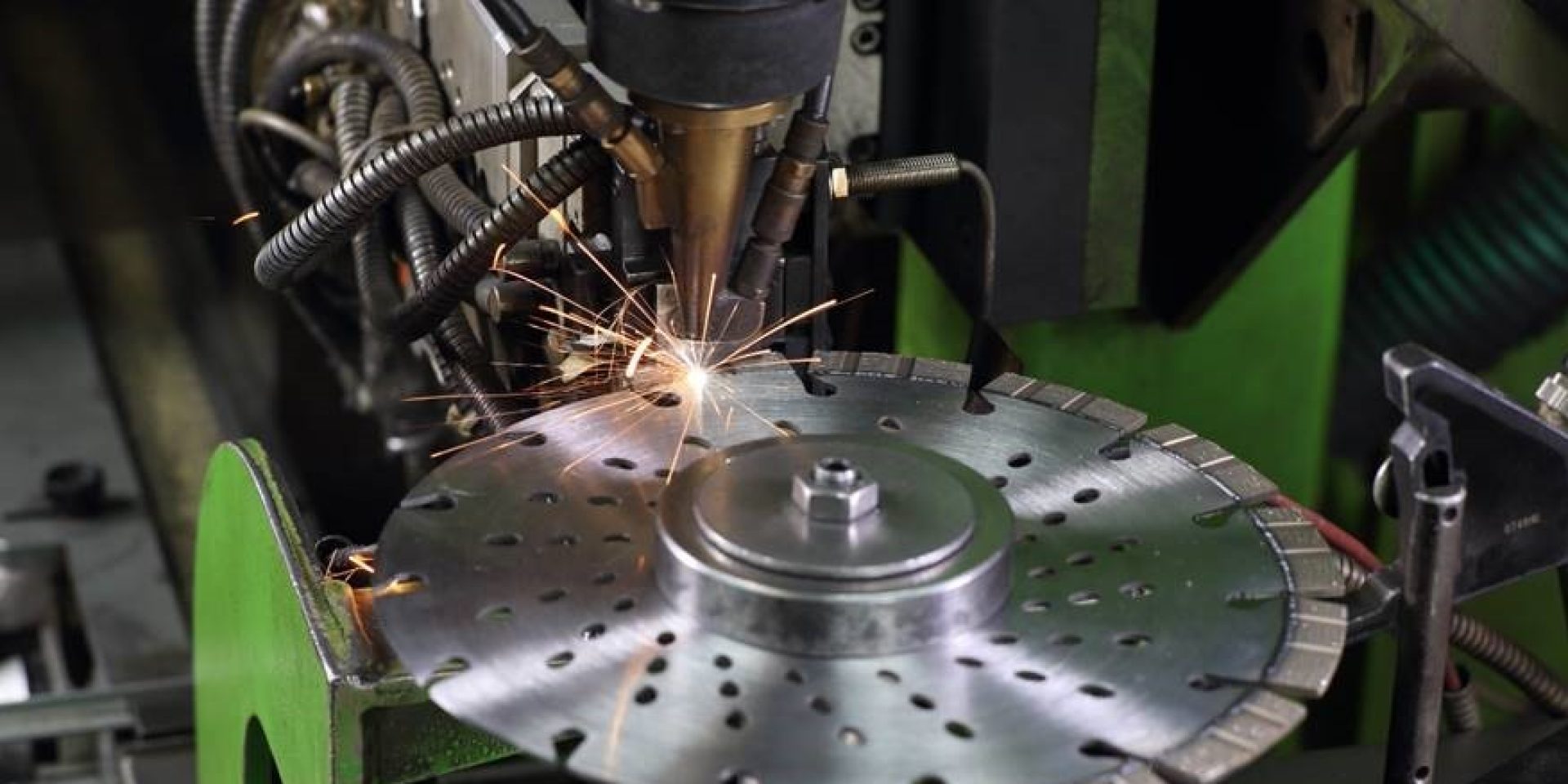

Our manufacturing plant in Schaan, Liechtenstein specializes in metal anchors, direct fastening elements, such as nails and fasteners, and diamond segments for core bits and saw blades.

The plant was founded in 1941 and was our first Hilti production facility. It has been extensively expanded and modernized over the years. The facility produced direct fastening elements when it was first opened but other products have been added to the manufacturing line since then.

The plant is located close to our Hilti Research and Development facilities – that is why our Schaan plant concentrates on developing and manufacturing innovative products before they’re available to our manufacturing plants worldwide. All operations are executed and improved continuously on the basis of Lean Manufacturing. The plant won the Swiss Lean Award, a prize for achieving top performance in lean management, as well as the Manufacturing Excellence Award in the field of process innovation.

360 employees work at our Schaan plant, including around 80 apprentices. The plant is one of the largest vocational training facilities in the Rhine Valley region.

Thüringen, Austria

Our plant in Thüringen, Austria specializes in machining technology, component assembly and the final assembly of our tools for drilling and demolition, diamond coring and sawing tools and fastening technology tools.

With dedicated teams for production technology development, machinery engineering & construction and tool prototype manufacturing plant 4 contributes significantly to innovation and speed in new product introduction.

The plant was founded 1970 and has steadily expanded since then.

The most recent expansions were in 2009 with the completion of a new production hall and in 2010 when final assembly production was relocated to Thüringen from our plant in Mauren, Liechtenstein.

400 employees work at the Thüringen plant, including 70 apprentices, making the plant one of the largest centers for vocational training in the region. In 2009 it was named the best vocational training operation in Austria.

Kaufering, Germany

Our plant in Kaufering, Germany manufactures motors, premium drill bits, anchor channels, bonded anchors and firestop products.

Our Kaufering plant develops and applies modern manufacturing concepts, technologies and processes, which are then shared with our production plants around the world. Kaufering also creates innovative products working with our marketing and development units.

The plant operates successfully according to lean manufacturing principles and has won the Manufacturing Excellence Award several times.

The plant runs a structured energy management system, making responsible use of energy and resources and has ISO 50001 certification.

The production facility is located near Munich and began operations in 1971.

It has 500 employees including around 65 apprentices.

Strass, Germany

Our Strass plant, Germany is our main plant for plastics technology.

The plant manufactures fastening elements such as plastic anchors and plastic components for our Hilti products.

We acquired the plant from the Fürstlich Hohenzollersche Hüttenverwaltung in 1975. It has been expanded many times with the latest expansion in 2010.

The plant is a center of excellence and focuses on product and production technology as well as all issues relating to materials.

It has 215 employees including 15 apprentices.

Kecskemét, Hungary

Chisels, special and lengthy drill bits, rock drill bits, hollow bits, saw blades for wall saws and diamond coring bits are manufactured at the Hilti plant in Kecskemét, Hungary.

The company was founded in 1989 and production capacity has regularly expanded. From 2004, apart from the manufacturing processes the test activities started with an increasing portfolio. Since 2013 the plant launched the NQA program for the manufacturing of HDA products.

The first production hall was completed in 1994 with a substantial expansion in 2010. In 2012 the production area was enlarged to cover roughly 12,000 square meters.

The plant in Kecskemét has established close ties with a number of Hungarian universities and technical colleges.

The plant employs around 250 people.

Matamoros, Mexico

Our plant in Matamoros, Mexico produces metal construction fasteners for our market organizations in the Western Hemisphere.

It includes state-of-the-art production technologies, including metal forming, stamping and machining plus electro-galvanic plating and automated assembly.

Matamoros started production in 2009. It has significantly increased supply capacities for customers in the Western Hemisphere.

The plant employs around 170 people.

Zhanjiang, China

Our plant in Zhanjiang, China was established in 1995 and has expanded steadily over the years. The most recent expansion took place in 2005 and doubled the plant area to 55,000 square meters.

The plant specializes in the production and refining of metal accessories and chemical anchors.

This includes finishing, coating and assembling metal anchors as well as manufacturing nails and basic epoxy.

The plant employs approximately 330 people.

Shanghai, China

Our production facility in Shanghai, China opened in 2004 and specializes in the production of light-duty power tools including corded and cordless electro-pneumatic hammer drills, corded and cordless screwdrivers, cordless saws and angle grinders, and more.

It employs around 470 people who develop, assemble and test the tools before shipping them to locations around the world.

The plant is located in the Xinzhuang Industrial Park and covers an area of 14,500 square meters.

Lanzenkirchen, Austria

Eurofox is based in Lanzenkirchen, Austria and was founded in 1993. The Hilti Group acquired the company in July 2011 and expanded the facilities in 2015. Today, the facility hosts manufacturing of Hilti’s innovative range of substructure systems for ventilated facades. It is also home to our development teams for ventilated façades, allowing us to test new solutions and ideas in constant alignment with production and supply.We further operate our own engineering office, which develops specific project designs for end-customers around the globe. Ventilated façade systems made by Eurofox are known for their high quality, long lifetime, high load-bearing capability and energy-efficiency. Hilti ventilated façade substructure systems have been used in many leading construction projects, such as the Gazprom Arena, in St. Petersburg, “The Corniche” towers, in London, or the 264-meter-high Triumph Tower, in Moscow.

Our global center of excellence for pipe fastening is also located at our site, where we develop highly productive and innovative solutions in the field of pipe clamps and pipe shoes.

The facility employs around 40 people in production and 80 people in office functions.

Navsari/Gujarat, India

Hilti Manufacturing India Private Limited produces cutting discs, large-blades, cup-wheels, core-bits for the global mainstream and the diamond-service contractor markets.

The company was founded in 1971 as Bhukhanvala Diamond Systems Private Ltd. In 2008 the Hilti Group, purchased 80 percent of the company, and in 2010 we purchased the remaining minority shares held by the founding family.

The company was then renamed in 2010 as Hilti Manufacturing India Private Limited. The four units of HMIPL located in Navsari, Gujarat, employ over 500 team members, and have in-house research, development, and testing teams and facilities.

HMIPL is ISO certified to ISO 9001:2015 and ISO 14001:2015 standards, and is specialized in powder mixing and compaction, free-sintering, and laser- and CD-welding technologies. The unit is also the only member of Organisation for Safety of Abrasives (oSa) from India.

The plant employs around 500 people.